ZeAllgrate fiberglass-reinforced plastic (FRP) ladder and cage systems meet or exceed OSHA requirements. Ladders are stocked in standard heights up to 24′-0 and taller heights may be accommodated using splice kits. Floor and wall mount kits facilitate easy installation.

Ladders may be ordered with or without safety cage kits. Dynarail cage components can be shipped in compact kit form for field assembly or fully assembled and ready for installation.

Ladder System

Strongrate® corrosion resistance fiberglass ladder are found throughout the world in a variety applications and industries where safety, low maintenance costs, easy installation and long service life are essential.

A variety of color choice:

The standard color is safety yellow, but any systems can be custom ordered to your specific color

requirements.

Safety Ladder System

OSHA (Occupational Safety Hazards Association) requirements for ladder and ladder systems

1. 90kgs concentrated load (minimum at center of rung)

2. Distance between ladder rungs maximum 300mm, minimum clear width between side rails of

400mm

3. Distance from centerline of rungs to wall in back of ladder shall be not less than 180mm

4. Cage required on ladders of more than 6m to a maximum unbroken length of 9m

5. Cage to extend minimum of 1000mm above of top of landing

6. Cage shall begin minimum 2100mm to maximum 2400mm above base of ladder (floor)

7. Cage shall not be less than 690mm in width

8. Cage hoop vertical bars shall be located at a maximum spacing of 40 degree around

circumference of the cage

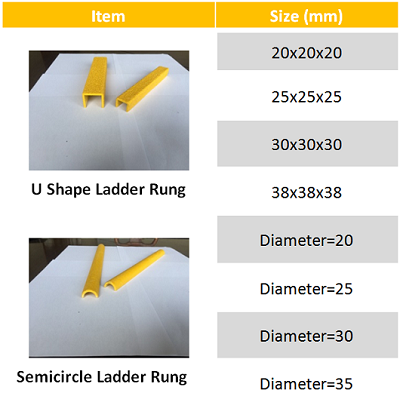

Ladder Rung System

Strongrate® FRP ladder rung system can make a non-skid ladder rung surface for the ladder no matter the material of ladder is FRP or traditional kinds, like steel or aluminum. We provide two kinds of ladder rungs: U shape ladder rung and semicircle ladder rung. The standard surface type is gritted surface (Quartz or Ceramic grit).

FRP Handrail

Handrail systems are fabricated with popular square posts and rails and are available in yellow or gray ISOFR resin. Posts are pre-routed to accept continuous rails and pre-drilled to facilitate efficient installation. Pultruded toe plate is commonly riveted to the post to provide a safe, complete, ready-to-install component. Grating Pacific will provide CAD drawings for field verification of all dimensions prior to fabrication.

Please contact us for complete technical data.

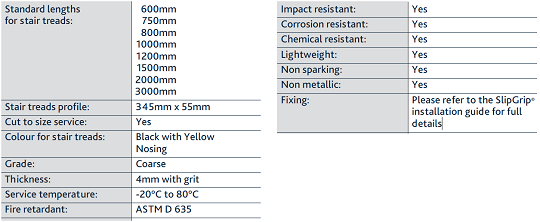

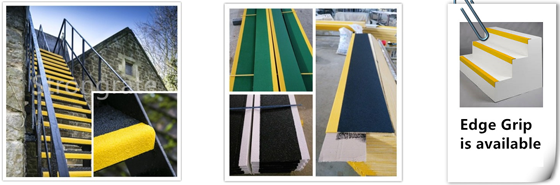

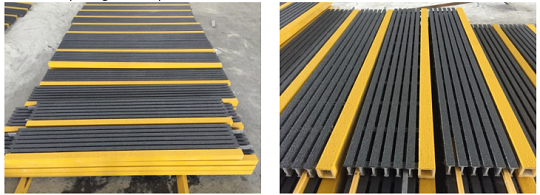

Stair Tread Cover

Strongrate® stair tread covers are a convenient way to provide solid, slip resistant footing for existing treads that are still structurally sound. Stair tread covers may be installed over wood,concrete or metal steps. Standard color is black with a highly visible safety yellow nosing for industrial applications and light gray for architectural applications. Custom color and size are always available.

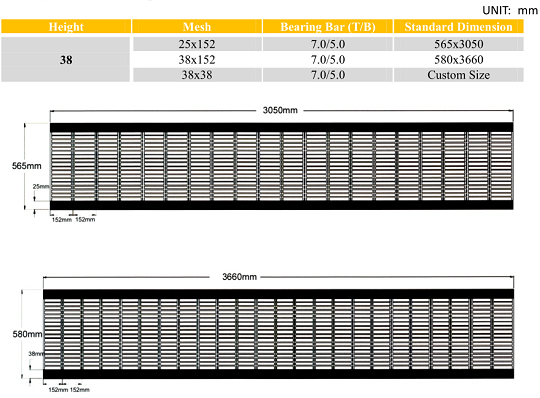

Technical Data

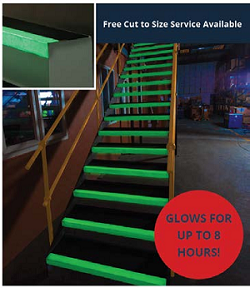

Safety Glow Type is available

Ideal for areas with limited light/Glows for up to 8 hours/55mm DDA compliant stair tread nosing/Building regulation compliant/Available with yellow or white nosing/Suitable for high pedestrian traffic

FabTread

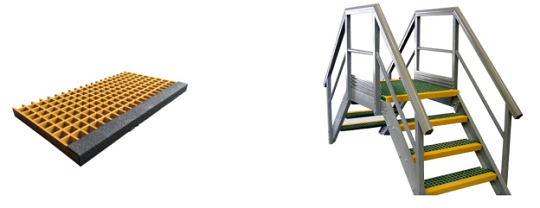

ZeAllgrate® molded fiberglass stair treads are offered in three versions.

The OSHA required non-skid nosing, built in to the leading edge of the tread for the first 32mm, is always gritted, and has the contrast color with the rest of the panel, normally in black.

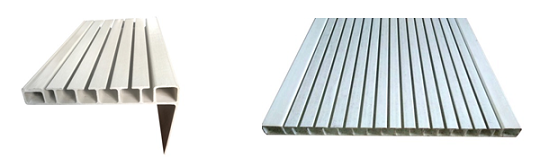

Pultruded Industrial/Pedestrian Stair Treads

Strongrate® slip resistant and non conductive, pultruded stair treads offer the same level of safety,strength and corrosion resistance as other Strongrate TM pultruded fiberglass products. Designed for use in industrial applications where wider support spans are required, pultruded stair treads are available in 25mm and 38mm depths in an I bar configuration with 40% and 60% open areas for most applications. A 50mm depth T bar configuration, with either a 33% or 50% open area, is also available for applications requiring wider spans or lower deflections.

Special Tread Covers Are Available!

ZeAll guarantees all items supplied for 15+ years!